JUMA

Separator - Filtering fabric

Industrial liquids filtering equipment

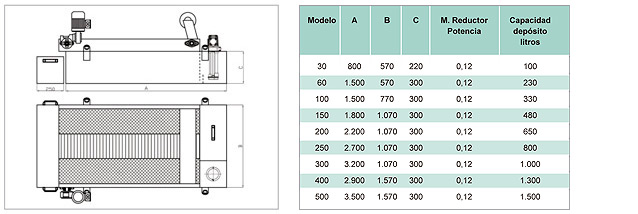

Specifications

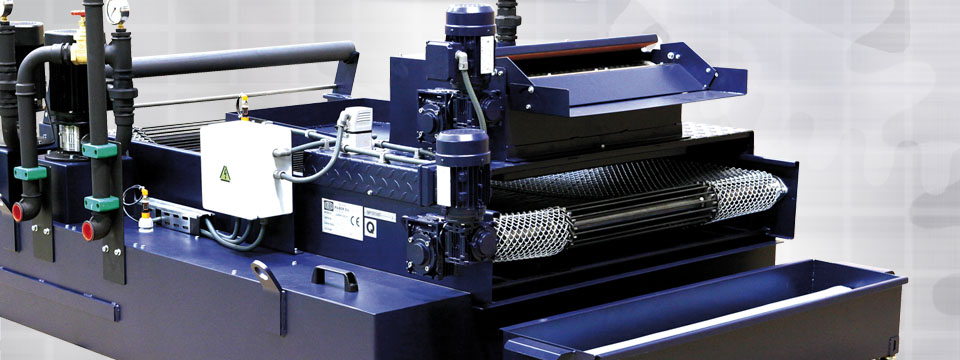

The JUMA separator with filtering fabric acts efficiently trapping chips and any particles present in cutting fluids (lubricants).

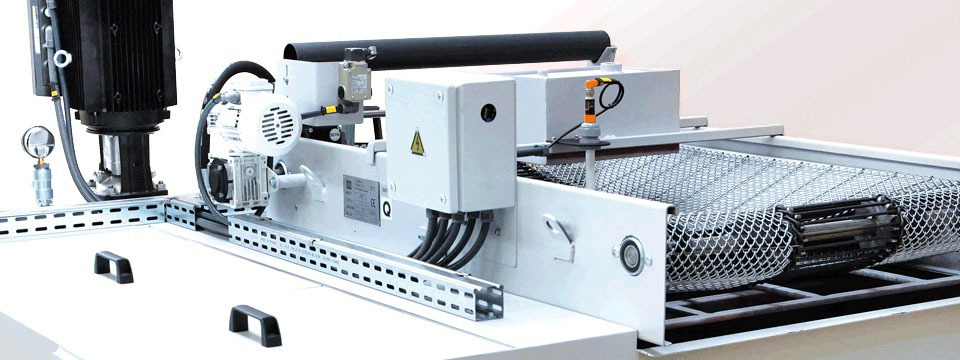

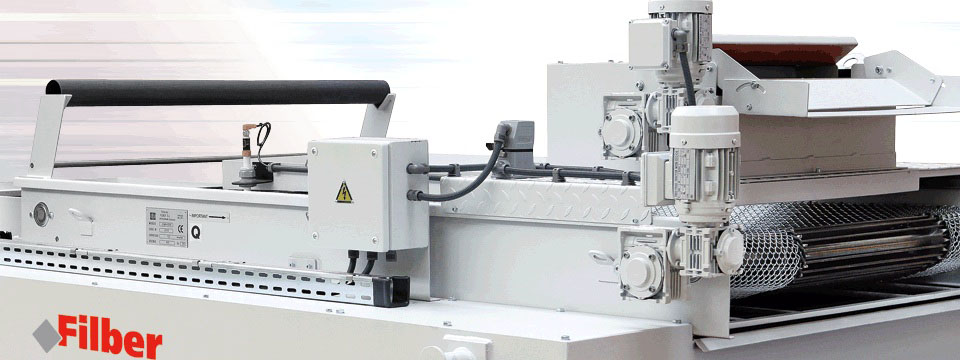

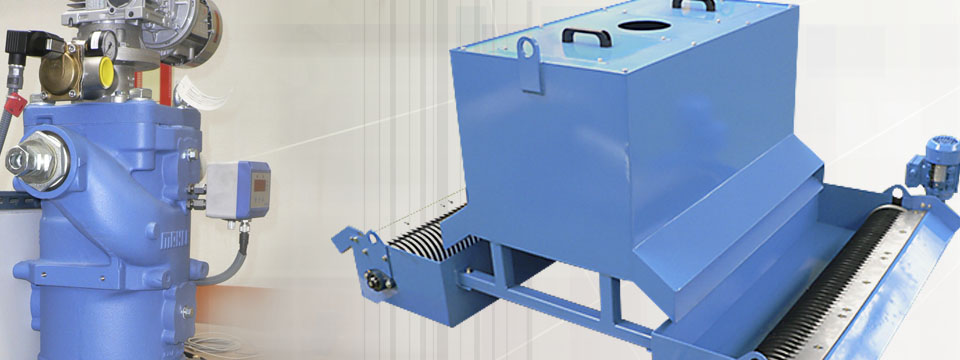

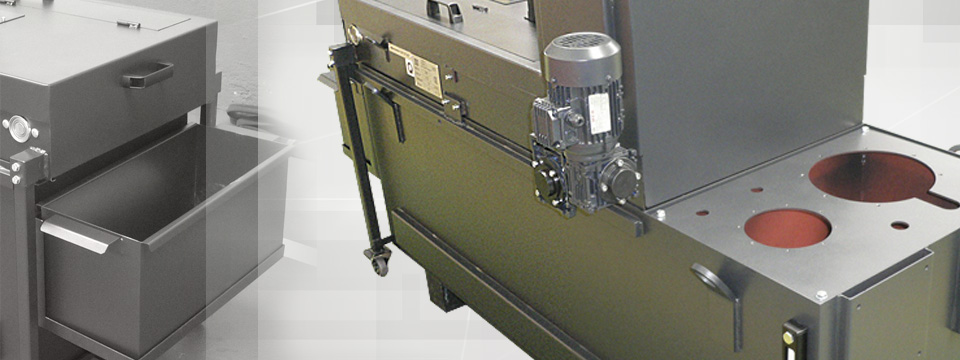

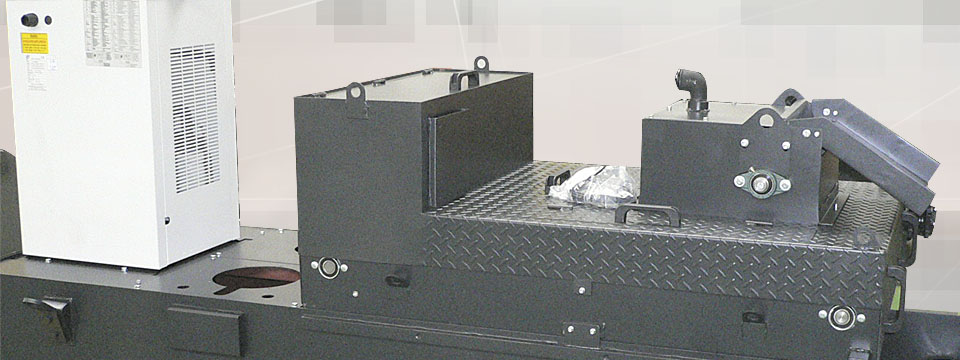

This filtering equipment consists of a tank (which can be stainless steel for the filtering of wastewater) on which a transmission is mounted, to which the filtering fabric is fitted.

The liquid to be filtered has to reach the strip of filtering fabric, extended over the conveyor mesh, where the impurities retained by the fabric build up. After a certain time, the impurities obstruct the passage of liquid, which builds up on the filtering fabric.

As the liquid level increases, it acts on a buoy that activates the gear motor. This moves the dirty filtering fabric and replaces it with new strip. This process is repeated every time the impurities block the passage of the liquid. The used, dirty filtering fabric is collected in a separate part of the tank.

This is a modular system, which allows for a very simple update to possible future requirements.

Advantages of JUMA

- It can separate any kind of impurities: brass, stainless steel, bronze, etc.

- Cost reduction on cooling liquids, cutting oils or lubricants, as you only need to replace the evaporated amount.

- Make the most out of your lubricant (up to 8 reuses).

- Reduce drastically machine downtime for the cleaning of tanks, gaining profitability in your production process.

- The stainless steel version is ideal for filtering wastewater.

Technical specifications

Accessories

Pumps, filters… all of it of the utmost quality.

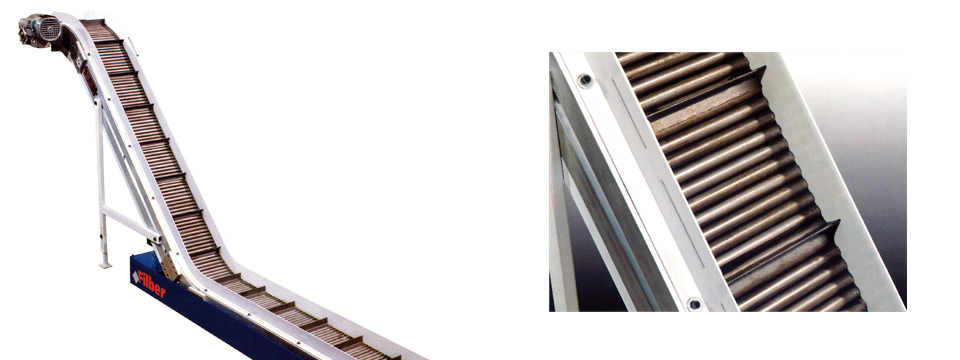

FILTRATION EQUIPMENT FOR OILS AND LUBRICANTS – CONVEYOR BELTS

FILTRATION EQUIPMENT FOR OILS AND LUBRICANTS – CONVEYOR BELTS

Juma

Juma  Gain / on Gain

Gain / on Gain  Juma + gain

Juma + gain  sistema limpieza juma

sistema limpieza juma filtro autolimpiante

filtro autolimpiante Jaso

Jaso  Igo

Igo